From an economic and strategic perspective, the cold chain holds immense value for companies. How does efficient cold chain management drastically reduce product losses and spoilage? The key lies in achieving end-to-end traceability and temperature visibility throughout transport and distribution.

Situation

For many companies and industries, maintaining control over the cold chain is extremely challenging—and in many cases, nearly impossible. Numerous factors, ranging from human error to technical and mechanical issues, can disrupt internal cargo temperatures, leading to food waste and the resulting economic and nutritional losses.

In the chemical and pharmaceutical industries, if temperature requirements are not met—even for a brief period—products become unsafe or degrade, as happens with a high percentage of vaccines, which—needless to say—is regrettable.

To minimize these losses, companies seek ways to implement real-time monitoring of the cold chain, so that deviations do not affect companies or businesses and, therefore, the end consumer or final recipient.

Moreover, therer goods and merchandise are also exposed to security risks and are targets of theft.

Problem

If temperature records are not kept during transportation, it becomes impossible to improve processes or identify the critical stages that lead to losses. As a result, companies are left to speculate and apply improvised solutions, without ever addressing the underlying issues.

Solución

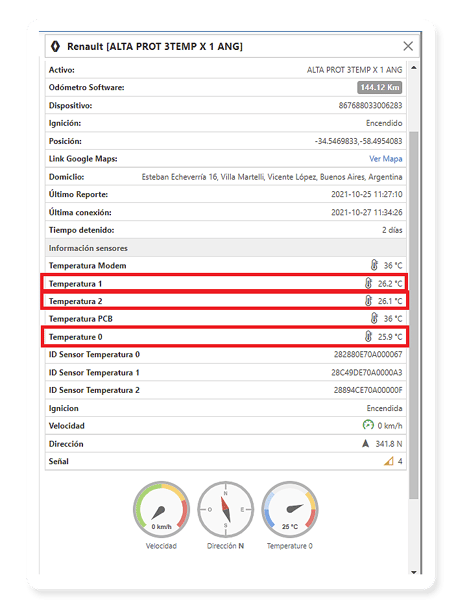

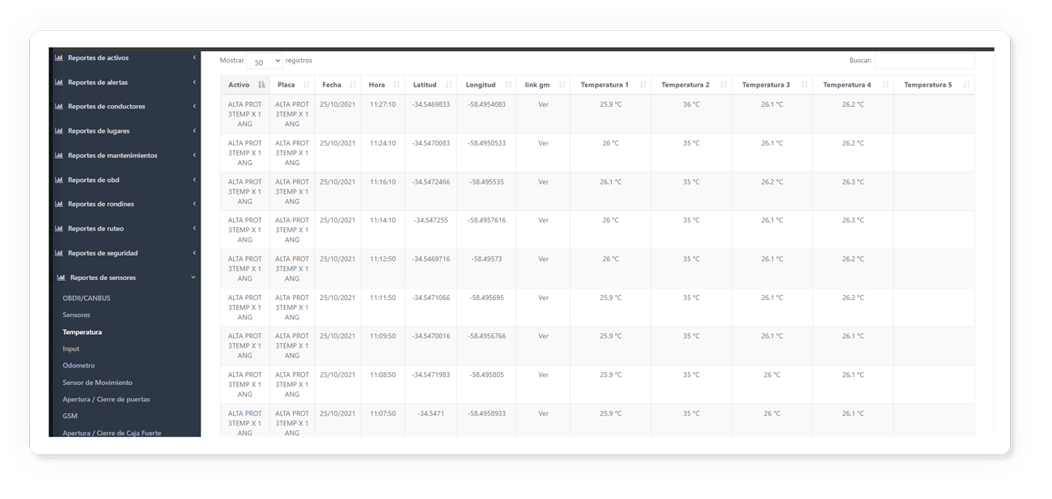

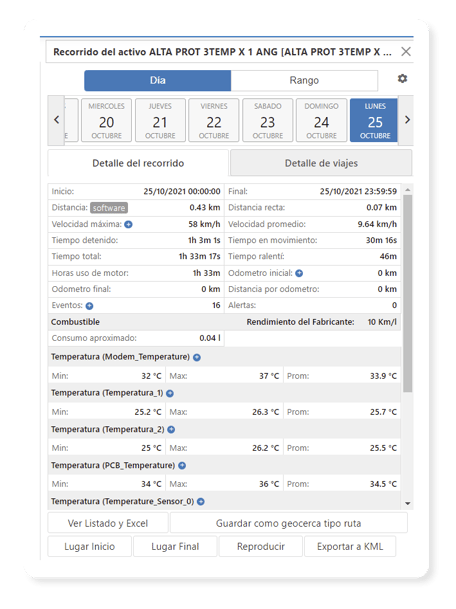

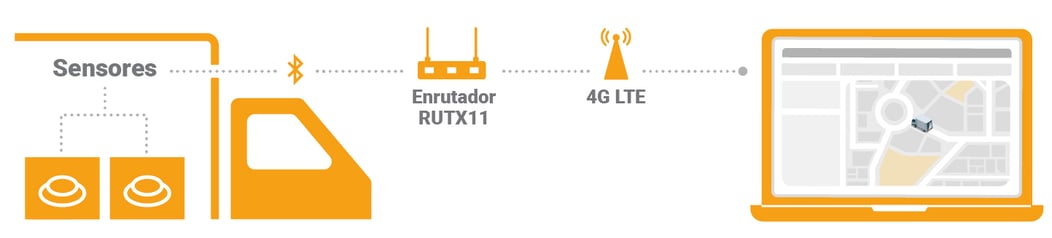

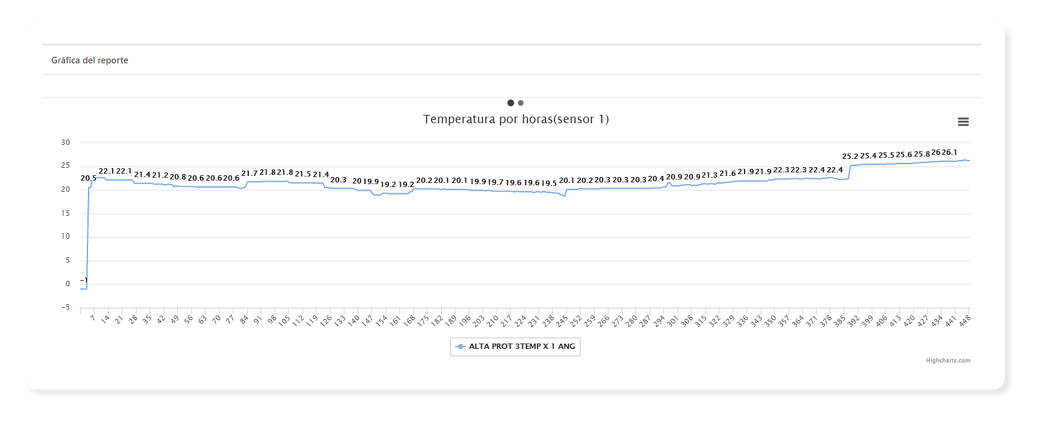

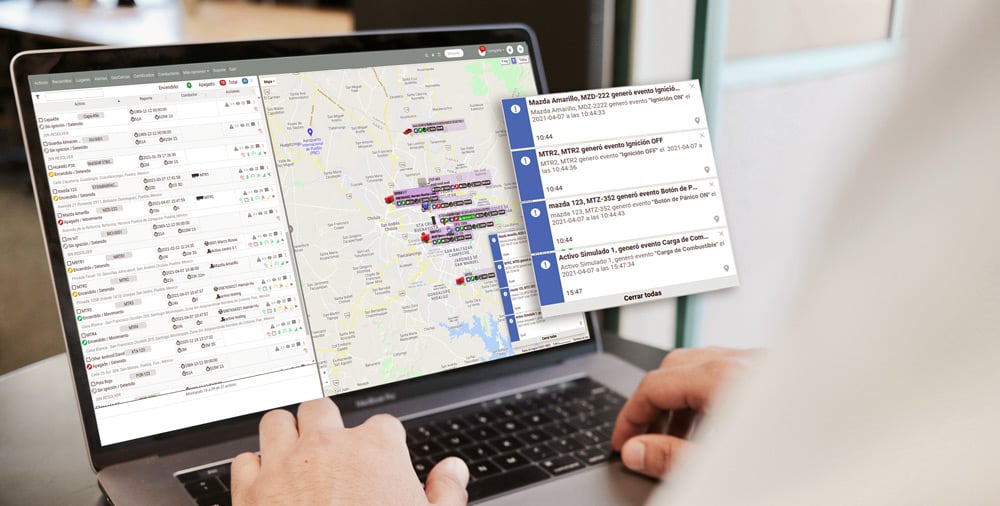

The cold chain can be safeguarded through efficient asset tracking, monitoring both the location and real-time temperature of shiments at every stage. Additionally, installing cameras provides video evidence in the event of theft or unauthorized door openings. To achieve this, we install Bluetooth sensors on pallets or product containers; these sensors may be ID-type (for equipment tracking), T-type (for temperature), RHT-type (for temperature and humidity), or others, depending on which metrics require monitoring. Using the Teltonika RUTX11 cellular router, we can connect up to 200 sensors; the router collects sensor data via Bluetooth and sends it to our OnTracking platform, where all devides can be configured and monitored in real time through the advanced detail dashboard.

The router features GNSS capabilities, enabling it to identify events occurring at specific locations such as whether proper temperatures were maintained throughout the journey, when and for how long the container door was opened, or if the refrigeration system was powered off. OnTracking processes all this data and transforms it into real-time reports.

Sensor data enables the configuration of alerts for any abnormal activity. For example, if the temperature rises or approaches a defined risk threshold, OnTracking notifies users or operators via in-platform messages and audible alerts, as well as through push notifications on the Mobile App, email, or SMS. This allows for immediate corrective action to prevent losses. This powerful hardware and software combination also makes it easy to track goods within the warehouse or throughout the route using the platform’s Route Module, delivering full supply chain visibility.

Implementation

In the vehicle, the following components are installed:

- Teltonika RUTX11 device.

- BLU temperature sensors.

On the OnTracking platform, the following configurations are made:

- Sensor list setup in the plataform.

- Alert configuration.

- Report scheduling and generation.

To address the needs of this use case, both the OnTracking software and the hardware sensors and router are highly critical components, as they provide the means for real time data collection and reporting, enabling comprehensive monitoring of all activity inside and outside the cargo.

Context

Proper temperature control is critical. Cold chain logistics costs account for between 15% and 20% of total logistics expenses at least 3% to 8% higher than those of a dry supply chain. According to data from chambers of commerce, by 2024 the demand for cold chain services is expected to increase by 76%, fueled by rising demand for food and pharmaceuticals.

According to data from the Food and Agriculture Organization (FAO), approximately 14% of the world’s food is lost every year in the first stage of the supply chain, before it reaches retail.

On the other hand, data from the World Health Organization (WHO) indicates that up to 25% of vaccines arrive at their destination in degraded conditions due to poor transportation.

For this reason, the cold chain presents significant opportunities—including expanded food production capacity, the adoption of disruptive technologies like IoT, cost reduction, improved decision-making, and ensuring compliance with each country’s regulatory requirements, among others.

Challenges

Help your customer analyze how these tools will make their service more reliable and competitive. Beyond temperature monitoring, there are additional solutions available to help grow their business and address challenges more effectively.

To guide this analysis, consider the following questions:

- Does your customer have complete control over the cold chain?

- Are their operations ready to adopt new technologies?

- Do their current capabilities support future demand?

- Do they have tools to manage resources such as fuel?

- Do they have video evidence backup to view any incident with their shipments in real time?

By reflecting on these and other questions that may arise during the conversation, you are sure to identify opportunities for improvement where your company can provide effective solutions.

Conclusions

Many companies seek to save on sensors or platforms without realizing they are putting their products at risk and harming their operations. That’s why it is essential to invest in technology that provides traceability and visibility of temperature ranges, ensuring total control of the cold chain from origin to destination.

With OnTracking tools, we optimized every transport involved in goods that require rigorous cold chain control. This solution enabled us to minimize economic losses and significantly increase the quality of service delivered to our customers.

You may also be interested in

The possibilities unlocked by Bluetooth 5.1 in GPS tracking |

What is a hardware-agnostic tracking plataform? |

LBS: What is it and how does it complement GPS tracking? |