Program and manage all fleet maintenance and generate budgets without the need for additional personnel

Discover the top 20 solutions and tools for tracking, security, and end customers

Discover how a virtual copilot in MDT terminals meets safety regulations and optimizes operations

How efficient cold chain control drastically reduces losses and damages to goods?

One of the most critical activities in logistics management is asset control...

Three out of ten engines run on stolen fuel. How did Neotecnik decide to stop this problem?

With the right tools and guidance, migration represents an improvement in the service you provide to your customers and strengthens your position against the competition

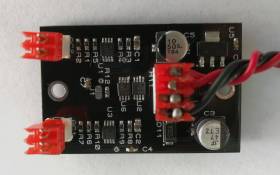

Design, integration, and production of a system for monitoring power consumption in a welding plant. The main card is capable of communicating via Ethernet to a local network, which allows the user to transmit and receive data such as power consumption, logical states of its four inputs (which can be dry contact or 24V input), as well as change the states of its relay outputs with commands. The system has a module that, along with a current sensor, transmits power consumption data via RS485 communication to the main card.

Design, integration, and production of a system for monitoring power consumption in a welding plant. The main card is capable of communicating via Ethernet to a local network, which allows the user to transmit and receive data such as power consumption, logical states of its four inputs (which can be dry contact or 24V input), as well as change the states of its relay outputs with commands. The system has a module that, along with a current sensor, transmits power consumption data via RS485 communication to the main card.